WasteWater Treatment

Discover our advanced wastewater treatment products designed for efficient and reliable performance, ensuring high-quality water for various industrial and municipal applications.

Rotary Drum Screen & Static Fine Screen

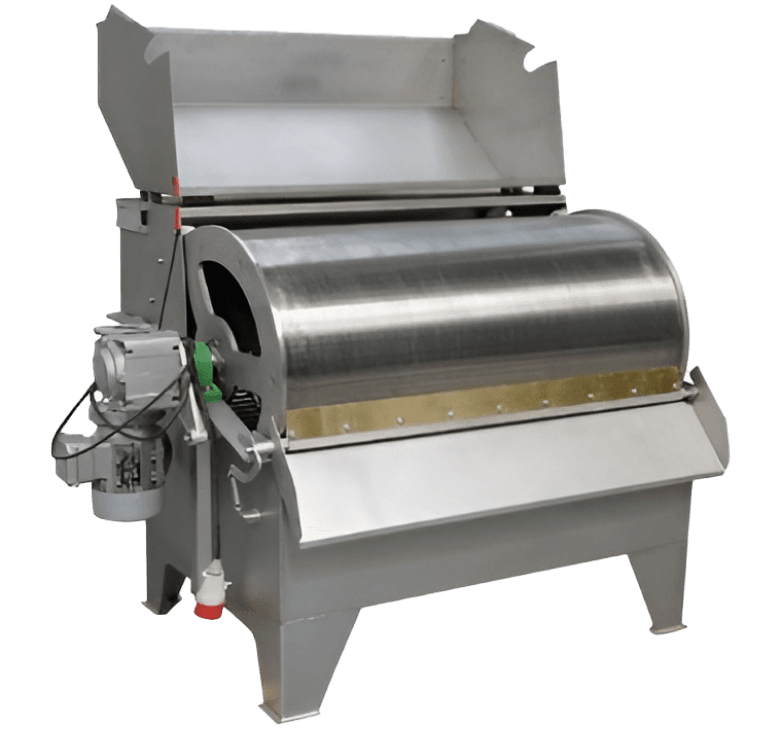

Rotary Drum Screen

This filtration device removes fine solids from wastewater. It features a rotating drum with mesh or perforations that trap particles while allowing clean water to flow through. Commonly used in industrial and municipal systems for efficient solid separation.

Static Fine Screen

This screen provides effective, low-maintenance filtration for wastewater treatment, capturing fine particles as water flows over the screen surface. Ideal for both municipal and industrial applications, these screens use gravity to separate solids without moving parts, offering a reliable, energy-efficient solution.

Coagulation & Flocculation Products

Coagulation Tank

This vessel is where chemical coagulants are added to destabilize and bind suspended particles into clusters, or “microflocs.” With rapid mixing for even coagulant distribution, the tank creates conditions ideal for downstream processes like sedimentation or Dissolved Air Flotation (DAF), enabling efficient contaminant removal.

Rapid Mixer

This high-speed device quickly disperses chemicals, such as coagulants, into water to ensure even distribution and initiate particle aggregation. Positioned before the coagulation tank, it prepares the water for effective downstream treatments, such as flocculation and Dissolved Air Flotation (DAF).

Flocculation Tank

This vessel allows gentle mixing allows small, destabilized particles (microflocs) can combine into larger clusters, or “flocs.” After coagulation, water enters the flocculation tank, where low-speed mixers slowly stir it, encouraging the formation of sizable flocs that are easier to separate. This process enhances the efficiency of subsequent treatments, like sedimentation and Dissolved Air Flotation (DAF), by making particles large enough to be easily removed from the wastewater.

Slow Mixer

This device gently stirs water in the flocculation tank, encouraging small particles to combine into larger flocs, making them easier to remove in downstream processes like sedimentation and Dissolved Air Flotation (DAF).

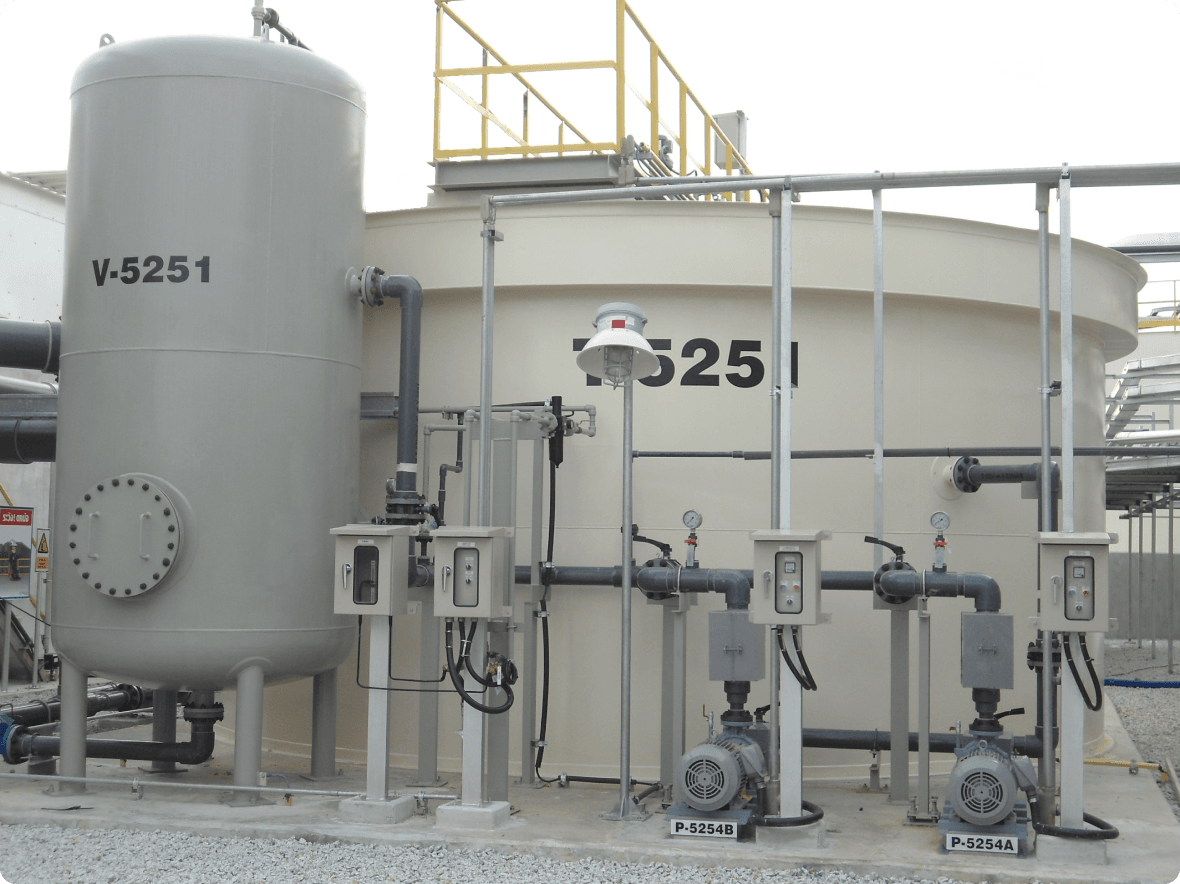

Chemical Feed System

This system accurately delivers chemicals, such as coagulants or pH adjusters, into the treatment process. It includes storage tanks, pumps, and controls that ensure precise dosing, preventing overuse while maintaining effective treatment.

Dissolved Air Flotation System (DAF)

A Dissolved Air Flotation Tank is a specialized vessel used in treatment to separate contaminants from wastewater. In the DAF tank, air is dissolved in water under pressure and then released, creating micro bubbles that attach to suspended particles. As the bubbles rise, they carry the particles to the surface, forming a froth layer. This froth is then skimmed off, effectively removing contaminants. The system is available in circular and rectangular designs and various sizes to match your flow rate requirements for optimal performance.

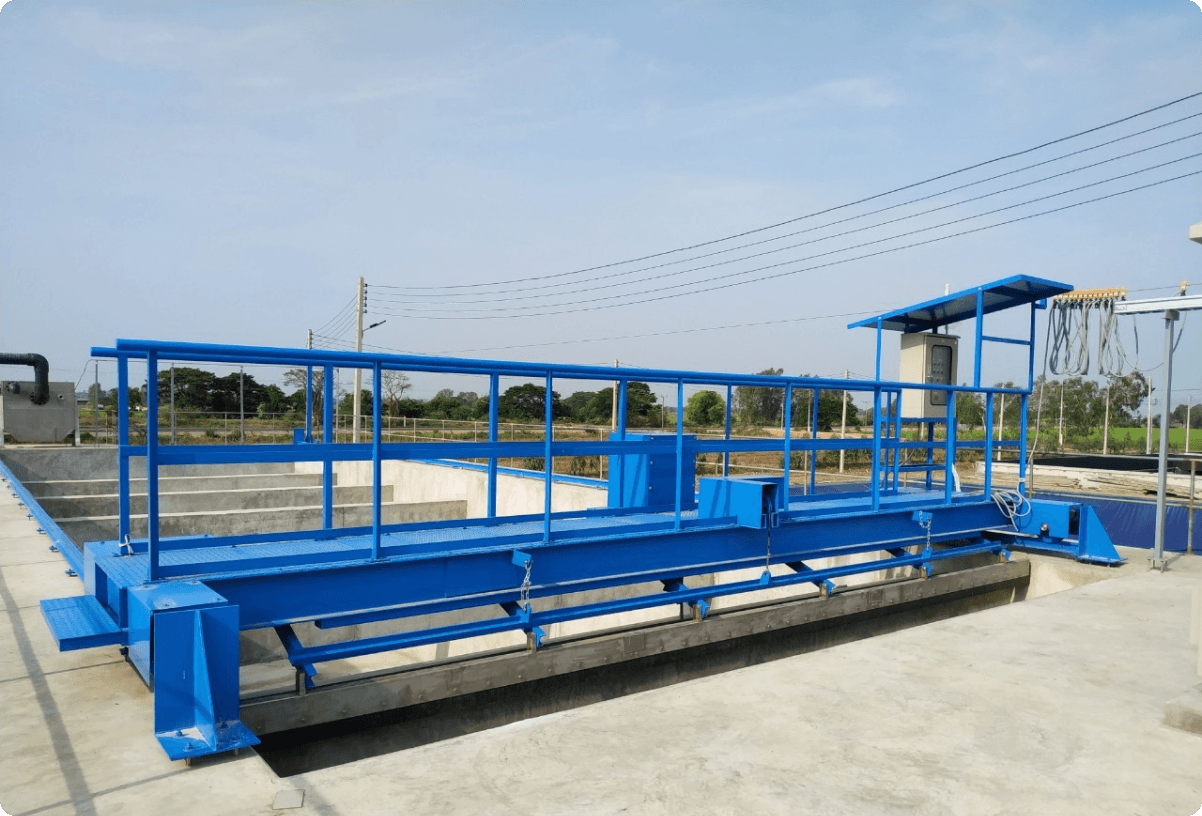

Travelling Bridge Oil Skimmer

A Travelling Bridge Oil Skimmer is a mechanical device used to remove oil and grease from water surface. It operates by moving a bridge across the water surface, with skimming mechanisms that collect floating oils into a collection trough. Commonly used in wastewater treatment and industrial applications, it provides efficient, continuous oil removal.

Sludge Dewatering Equipment

Sludge dewatering equipment is used to reduce the water content of sludge in wastewater treatment processes, making it easier to handle and dispose of.

1

Belt Filter Press

A mechanical device that uses two porous belts to squeeze water from the sludge as it passes through, producing a drier cake for disposal.

2

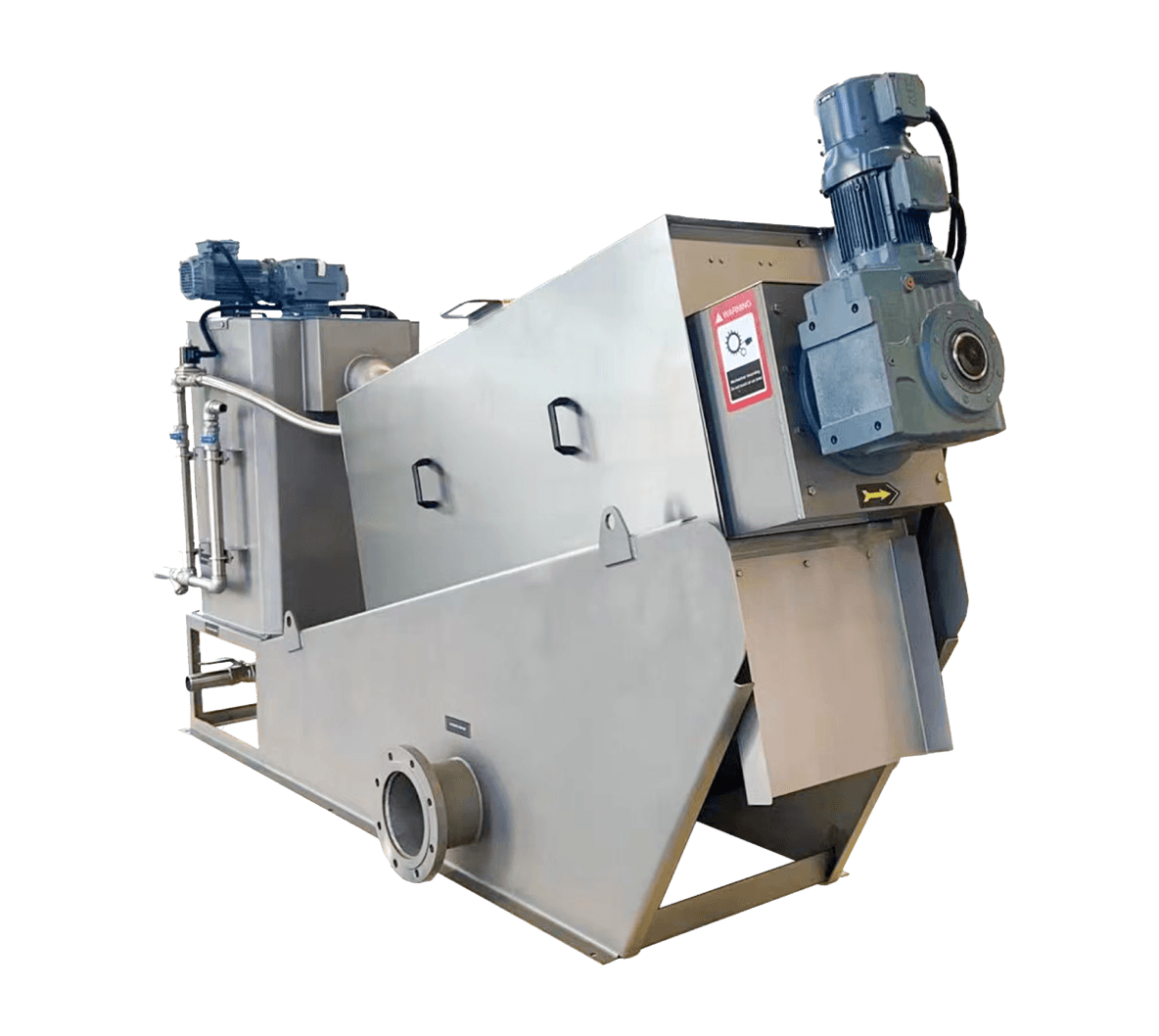

Screw Press

A continuous dewatering method that uses a screw mechanism to apply pressure, effectively separating liquid from solids.

3

Filter Press

This device uses pressure to force sludge through filter plates, resulting in high solids content and low water content in the final cake.

Gas-Locked Siphon Decanter

Our Gas-Locked Siphon Decanters offer precise, reliable separation of clarified water from settled sludge in wastewater treatment applications. Utilizing a unique siphon mechanism controlled by air, the decanter prevents sludge disturbance while maintaining a consistent water level, making it ideal for sequencing batch reactors (SBR System) and similar processes.

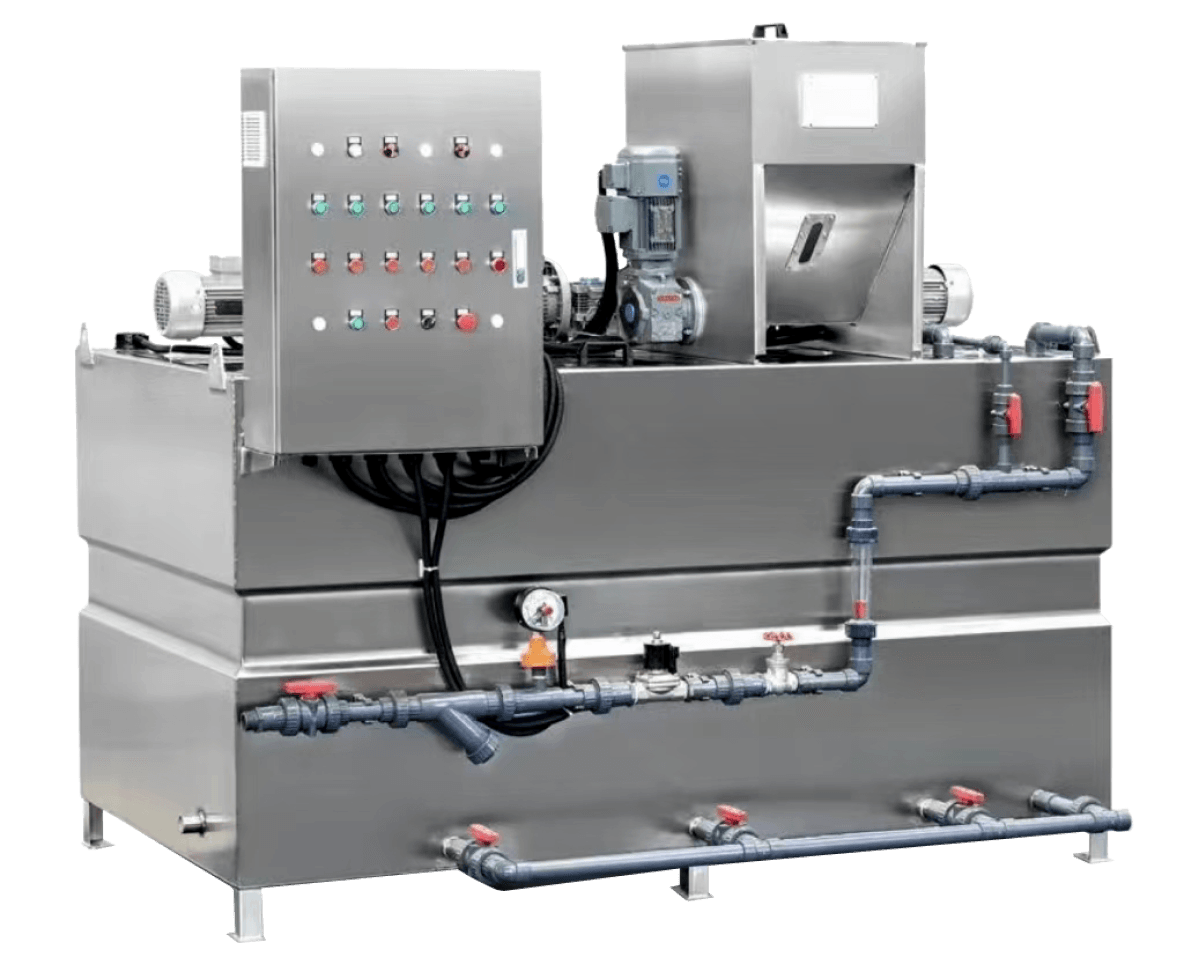

Automatic Polymer Preparation Unit

Automatic Polymer Preparation Unit ensure consistent and efficient polymer mixing for wastewater treatment. Designed to optimize polymer dosing, these units automate the preparation, activation, and dosing processes, maximizing polymer effectiveness while reducing manual handling.

RELATED PRODUCTS

Water Treatment System Products

Learn More

Recycle Systems Products

Learn More

Water Treatment for Cooling Systems Products

Learn More

Talk to an Expert

Contact us to discuss your needs and discover the right solution for you.

cservice@dynamic-th.com

Phone

+66 2-722-3470