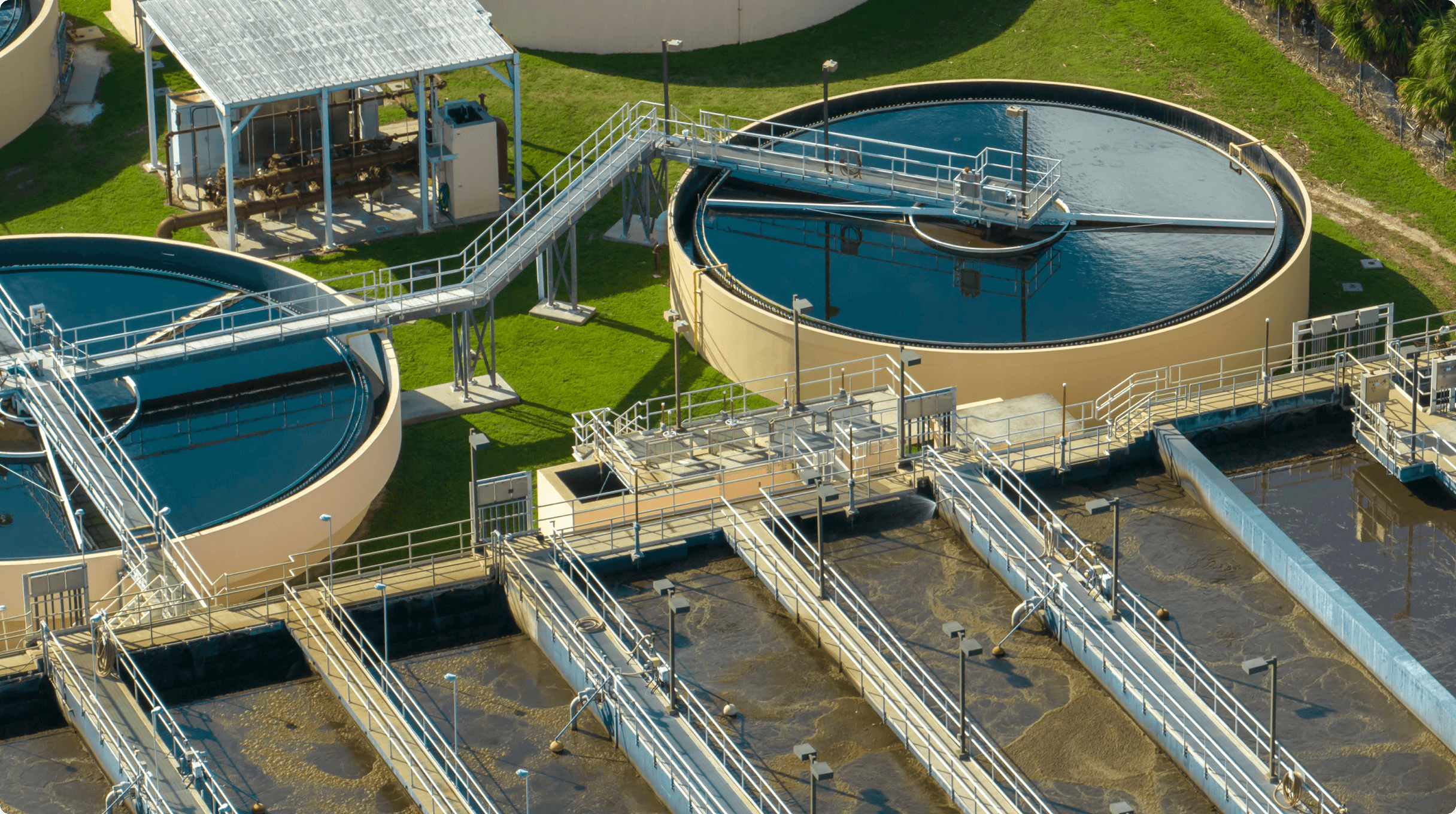

WasteWater Treatment System

Our Wastewater Treatment System offer efficient, reliable solutions for treating wastewater, ensuring compliance with environmental standards while protecting ecosystem and improving operational performance.

Screening System

Our advanced screening system are the critical first step in the wastewater treatment process. Designed to protect downstream equipment and ensure optimal system performance, screening plays a vital role in removing large solid debris and non-organic materials from the wastewater before it enters the treatment facility.

We offer a range of highly efficient screening technologies tailored to handle various flow rates and waste types, including:

Automatic & Manual Bar Screen

Automatic Rotary Drum Screen

Coagulation and Flocculation System

We utilize cutting-edge chemical coagulation and flocculation systems as critical steps in wastewater treatment. These processes are essential for improving water quality by removing suspended solids, organic materials, and other contaminants that cannot be filtered through physical screening alone.

We offer high-performance coagulation and flocculation systems designed to meet the specific needs of your operation. Our systems are engineered for efficiency, ensuring maximum contaminant removal while minimizing chemical usage and operating costs.

Dissolved Air Flotation System (DAF)

With over 35 years of experience, we specialize in Dissolved Air Flotation (DAF) system, offering efficient and reliable solutions for removing suspended solids, oil & grease, BOD, COD and other contaminants from wastewater. Our expertise ensures that our DAF system delivered high performance across diverse industrial and municipal applications.

Backed by over three decades of experience, we provide turnkey DAF system tailored to your specific needs. Our end-to-end solutions include installation, regular maintenance, and expert support, ensuring your wastewater treatment operations remain efficient and compliant.

Applications of DAF

Industrial Wastewater Treatment: Ideal for handling oily effluents.

Municipal Wastewater: Effective in solids removal for cleaner, more efficient systems.

Food & Beverage Industry: Specialized in removing fats, oils, and greases from wastewater.

Oil & Grease Removal System

We provide advanced Oil & Grease Removal System designed to efficiently extract fats, oils, and greases (FOG) from wastewater streams. These contaminants can cause blockages, equipment damage, and environmental harm if left untreated. Our systems ensure that wastewater meets regulatory standards while protecting your equipment and processes.

We offer a range of solutions tailored to various industrial needs and wastewater conditions. Our systems are designed to handle high levels of FOG while maintaining operational efficiency.

Activated Sludge Treatment System (AS)

We specialize in Activated Sludge (AS) Treatment System, providing reliable and efficient biological treatment for removing organic pollutants from wastewater. With over 35 years of experience, DES is a trusted leader in delivering AS systems designed for long-term reliability and performance.

From initial design to installation and ongoing support, our tailored solutions ensure efficient wastewater treatment for a wide range of applications. Our extensive experience guarantees that our AS system meet demanding environmental standards, offering effective solutions for both municipal and industrial wastewater treatment.

Sequencing Batch Reactor (SBR)

Unlike conventional continuous flow system, the Sequencing Batch Reactor (SBR) treats wastewater in timed cycles, each consisting of multiple phases within a single reactor. This batch operation allows for controlled biological treatment, TKN removal and high-quality effluent. The typical SBR cycle includes the following stages:

1

Fill

Wastewater is introduced into the reactor.

2

React (Aeration)

Aeration begins, encouraging microorganisms to break down organic pollutants.

3

Settle

Aeration stops, allowing solids to settle at the bottom of the reactor.

4

Decant

The clear treated wastewater is drawn off the top, leaving the sludge behind.

5

Idle

The system prepares for the next cycle, and excess sludge is removed as needed.

DES provides reliable and scalable Sequencing Batch Reactor (SBR) systems. Our systems are built with advanced control technologies that enable efficient, automated operation, ensuring optimal treatment performance. From design to installation and ongoing support, we tailor our solutions to your specific needs, ensuring long-term reliability and cost efficiency.

Heavy Metal Removal System

At DES, we specialize in effective and reliable Heavy Metal Removal System, designed to treat wastewater contaminated with hazardous metals such as lead, mercury, cadmium, chromium, and zinc. With over 35 years of experience, we deliver customized solutions to ensure safe discharge and compliance with environmental regulations, protecting ecosystems and public health.

Our Heavy Metal Removal Technologies include:

Chemical Precipitation

Ion Exchange

Electrochemical Treatment

Membrane Filtration

Adsorption System

Moving Bed Bio Reactor (MBBR)

The Moving Bed Biofilm Reactor (MBBR) process utilizes a carrier medium, typically small plastic media, that provides a surface for biofilm attached growth. As wastewater flows through the reactor, microorganisms attach to the media and break down organic matter.

Key Benefits of MBBR Systems:

1

High Treatment Efficiency

Achieves significant reductions in BOD, COD, and TSS.

2

Compact Design

Requires less space than conventional treatment systems, ideal for facilities with limited space.

3

Robust Performance

Handles varying loads and fluctuating flow rates, making it suitable for a wide range of wastewater sources.

4

Reduced Sludge Production

Handles varying loads and fluctuating flow rates, making it suitable for a wide range of wastewater sources.

5

Minimal Maintenance

Designed for easier maintenance and operation.

Sludge Dewatering System

Our Sludge Dewatering System use a combination of mechanical and chemical processes to effectively reduce the water content in sludge. The key equipment include:

1

Belt Filter Press

A mechanical device that uses two porous belts to squeeze water from the sludge as it passes through, producing a drier cake for disposal.

2

Screw Press

A continuous dewatering method that uses a screw mechanism to apply pressure, effectively separating liquid from solids.

3

Filter Press

Uses pressure to force sludge through filter plates, resulting in high solids content and low water content in the final cake.

DES is a trusted partner in delivering Sludge Dewatering System that ensure efficient solid waste management. Our expert team works closely with you to design and implement system tailored to your facility’s specific needs, guaranteeing optimal performance and compliance with environmental regulations.

From system design and installation to ongoing maintenance and support, we are committed to helping you achieve your wastewater treatment goals.

EXPLORE MORE SERVICES

Talk to an Expert

Contact us to discuss your needs and discover the right solution for you.

cservice@dynamic-th.com

Phone

+66 2-722-3470